Mastering the fundamentals of industrial sealing technology has become a critical competency for engineers, maintenance professionals, and facility managers across all sectors of manufacturing and processing industries. In today’s competitive industrial landscape, preventing leakage and maintaining system integrity isn’t just good practice—it’s essential for operational efficiency, safety compliance, and environmental protection. With proper sealing solutions, companies can significantly reduce downtime, minimize product loss, and extend equipment life, ultimately improving their bottom line.

The critical role of industrial seals in modern manufacturing

Industrial seals serve as the unsung heroes of process equipment, working silently to contain fluids, prevent contamination, and maintain pressure differentials. Their failure can lead to catastrophic consequences—from production halts and environmental violations to workplace hazards. Yet despite their importance, sealing technology is often overlooked until problems arise.

The science behind effective sealing involves understanding the complex interplay between mechanical design, material properties, and operational conditions. Temperature fluctuations, chemical exposure, pressure variations, and mechanical stress all impact seal performance. This complexity explains why mastering the fundamentals of industrial sealing technology requires both theoretical knowledge and practical experience.

Understanding gasket material selection principles

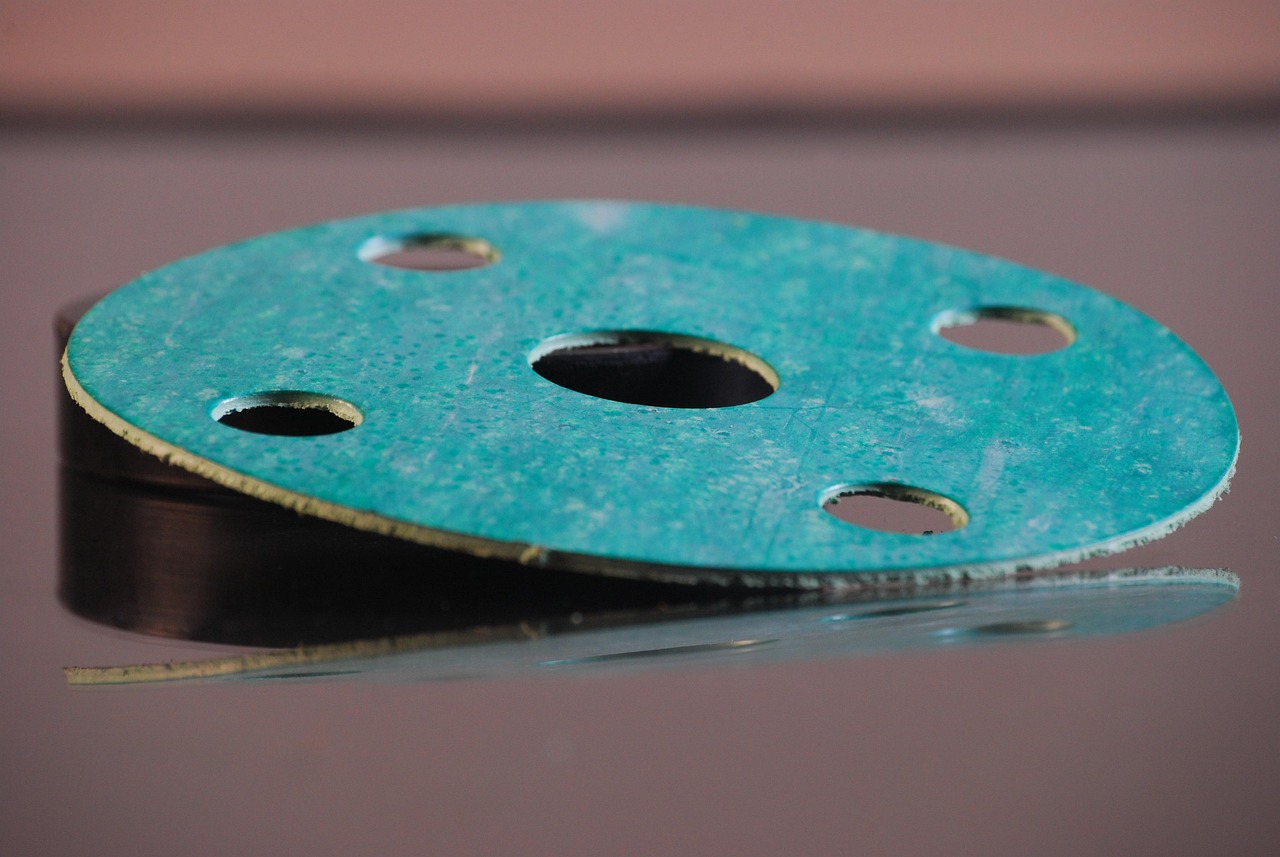

Selecting the appropriate gasket material represents perhaps the most crucial decision in sealing application engineering. The wrong choice can lead to premature failure, while the right selection ensures long-term reliability and safety. Gasket materials must be compatible with the media they contact, capable of withstanding operational temperatures, and resilient enough to maintain a seal under varying pressure conditions.

Elastomers like nitrile rubber excel in applications involving petroleum products, while fluoroelastomers offer superior chemical and temperature resistance. For high-temperature scenarios, particularly in exhaust systems or process equipment handling extreme heat, a graphite gasket sheet provides exceptional thermal stability. These flexible graphite sheets can withstand temperatures exceeding 450°C while maintaining excellent sealability and resistance to chemical attack.

When dealing with highly corrosive chemicals, PTFE (polytetrafluoroethylene) gaskets offer unmatched chemical resistance across a wide pH range. However, their creep characteristics and thermal expansion properties must be carefully considered during installation and maintenance. For general industrial applications, compressed non-asbestos fiber materials provide a cost-effective solution with reasonable chemical and temperature resistance.

Advanced considerations for high-performance sealing

Advanced considerations for high-performance sealing

Beyond basic material selection, mastering the fundamentals of industrial sealing technology involves understanding the mechanical behavior of gaskets under compression. The concept of “gasket stress” refers to the compressive force per unit area applied to the gasket. Insufficient stress leads to leakage, while excessive stress causes gasket crushing and failure. Calculating and maintaining proper gasket stress throughout the operational life of the seal requires consideration of bolt torque, flange rigidity, and gasket recovery properties.

Surface finish quality of the mating flanges significantly impacts sealing performance. Even the most advanced gasket material cannot compensate for severely damaged or improperly machined flange surfaces. Engineers must specify appropriate surface finish requirements and ensure proper preparation before gasket installation. This attention to detail exemplifies why industrial sealing represents a specialized discipline rather than merely an afterthought in equipment design.

The evolution of graphite gasket sheet technology

The development of graphite gasket sheet materials represents one of the most significant advancements in industrial sealing technology over the past several decades. Traditional asbestos-based materials once dominated high-temperature applications, but health concerns prompted the industry to develop safer alternatives. Flexible graphite emerged as the premier replacement, offering superior performance characteristics alongside improved safety.

Modern graphite gasket sheets typically consist of exfoliated natural graphite, sometimes reinforced with metal inserts or blended with other materials to enhance specific properties. Their exceptional conformability allows them to fill microscopic imperfections in flange surfaces, creating a tight seal even with less-than-ideal surface conditions. This characteristic makes graphite particularly valuable in maintenance scenarios where perfect flange preparation may be impractical.

The thermal stability of graphite gasket material extends beyond simple temperature resistance. Unlike many polymeric materials that degrade or oxidize at elevated temperatures, properly manufactured graphite maintains its sealing properties through countless thermal cycles. This resilience makes it ideal for applications subject to frequent startups and shutdowns, where thermal expansion and contraction continuously stress the sealing system.

Implementing effective installation practices

You can have the perfect gasket material, but improper installation will inevitably lead to premature failure. Correct bolt tightening sequences, appropriate torque values, and proper alignment of mating components all contribute to successful seal performance. Training maintenance personnel in these practices represents a high-return investment for any industrial operation concerned with reliability.

When installing graphite gasket sheets or other compressed sealing materials, technicians should follow manufacturer-recommended torque patterns, typically applying torque in multiple stages to ensure even compression. This methodical approach prevents gasket damage and promotes uniform stress distribution. Additionally, monitoring bolt torque during the first heating cycle can identify potential problems before they lead to leakage.

Future trends in industrial sealing technology

The industrial sealing industry continues to evolve, with innovations focusing on longer service life, improved reliability, and reduced environmental impact. Nanomaterial-enhanced gaskets offer improved performance characteristics, while advanced manufacturing techniques allow for more precise control of material properties. Computational modeling tools now enable engineers to predict seal behavior under complex operating conditions, optimizing designs before physical prototypes are created.

Smart sealing systems represent an emerging frontier, incorporating sensors that monitor seal condition and performance in real-time. These technologies align with broader Industry 4.0 trends, providing predictive maintenance capabilities that can prevent catastrophic failures and optimize replacement schedules. For professionals committed to mastering the fundamentals of industrial sealing technology, staying abreast of these developments is essential for maintaining competitive advantage.

The pursuit of excellence in industrial sealing technology requires ongoing education, experience with diverse applications, and commitment to continuous improvement. By understanding core principles and emerging trends, engineers and maintenance professionals can ensure their sealing systems deliver optimal performance under even the most demanding conditions.